Lego’s revenues for 2017 are now out. In September 2017, Financial Times reported on problems at Lego, which was then planning to cut about 8% of its workforce. Indeed, Lego has been suffering from increasingly bigger global operations problems, with poor sales in Europe and North America. There have been reports of inventories piling up at distribution centers.

One of the reasons attributed for Lego’s troubles is that Lego has been distracted from its core competencies, by investing in movie franchising and so on. While that is partly true, as I will explain below, Lego’s core business itself has some fundamental issues, that need to be resolved.

Let’s look at some Data and I point out two issues with Lego’s Operations Planning.

Data:

First, let’s look at some data on Lego and market trends in the toy industry. (Data: Quartz, and sources therein).

Tracking several years of data, for Lego, this is the first negative growth in revenues since 2004, and also the first drop in net profits since 2007. (Note: Data is in Danish Kroner. 2017 Revenue was 35Billion DKK which is about 5.78 billion USD). Peering into the 2017 Lego annual report summary, one can see some worrisome signs.

Compared to its competitors Hasbro and Mattel, Lego’s net profits have been higher but have been flat recently.

Toy companies have traditionally relied on holiday season brick & mortar sales. Those retail store sales (think ToysRus) are being obliterated by Amazon’s growth into the business. According to One Click Retail’s “Toys On Amazon: 2017 Review” report, Amazon sold an estimated $4.5 billion in U.S. toy sales during 2017. (That sales figure looks very comparable to Lego’s revenues). I am not so sure how much of Amazon’s Toy sales are from Lego products.

So, what are Lego’s problems?

Let us start at basics. Lego’s products are plastic injection molds. So, what makes Lego products so expensive?

Every single Lego brick made has to fit together perfectly with every other Lego brick EVER MADE. So the piece you get in your new super star destroyer has to snap together perfectly with a piece from a model house made in 1970. To achieve this, they run size tolerances on the order of .0005″.

Although the injection molding process is a cheap, repeatable, and extraordinarily scaled production process, what made Lego a bit more complicated historically was the “high tolerance specs”, which could justify running the production in Denmark. But, over time, China has caught up, both in production capability and costs. Lego eventually opened a production facility in China.

Let’s take a look at the “bones” of the Lego “brick” supply chain.

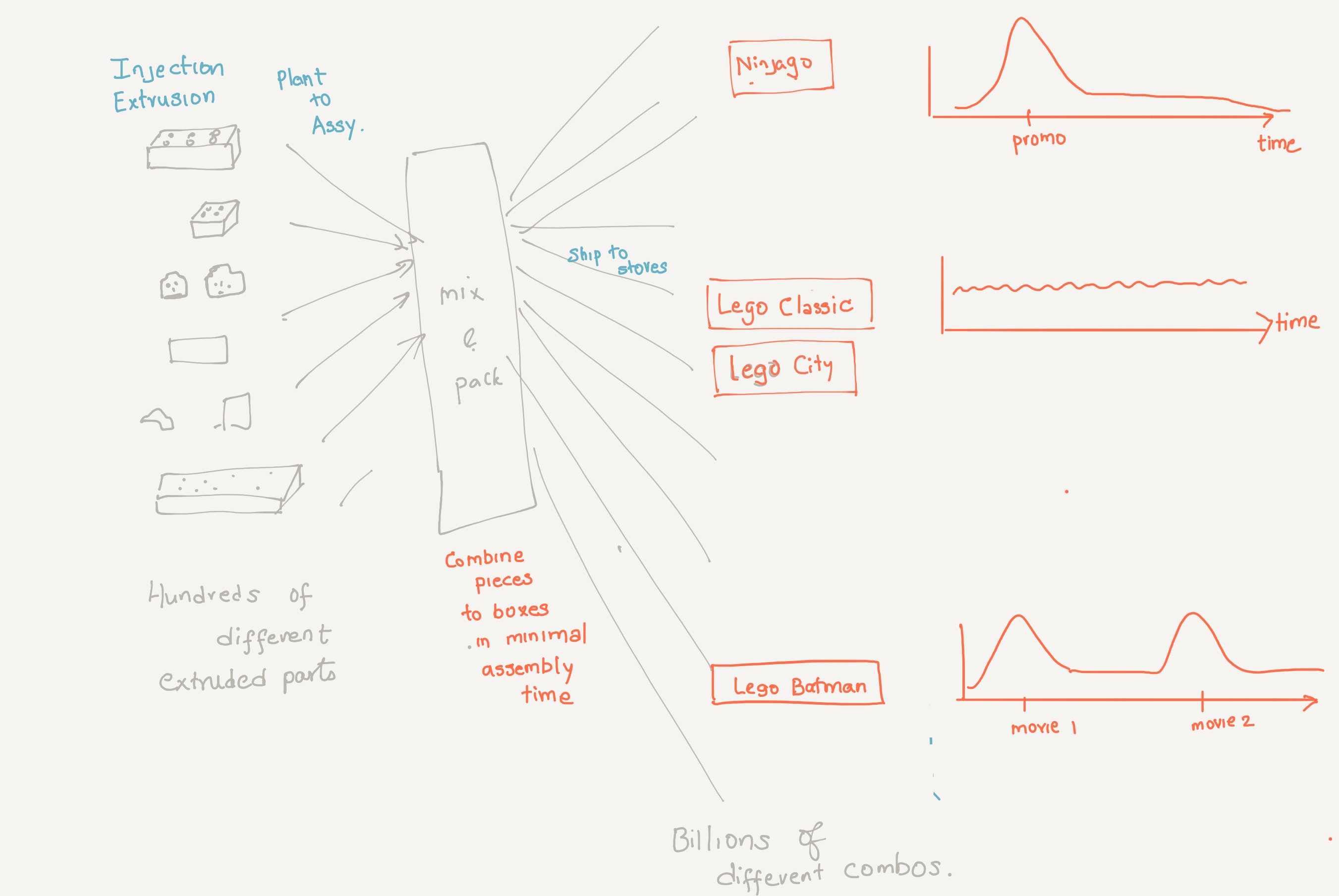

Issue 1: Capacity Utilization vs. Reacting Quickly to Demand

Lego manufactures hundreds of different parts (maybe, a few thousand). But, the point I am making holds despite the numbers (see the left hand side of the Figure above). The number of different SKUs manufactured in production plant pales in comparison to the BILLIONS of different combinations that can be made by mixing and matching. This alludes to the large number of products/themes they can create bring to market. In fact, this is precisely the factor that increases the fun “playtime” utility of Lego, when combined with its product durability and longevity. Families can make Lego assemblies to engage in a variety of imaginary theme plays.

The exploding number of product combinations poses the following unique challenge (for LEGO compared to other toymakers): LEGO just cannot choose to make different combinations of boxes and have them on shelves. If some theme or product does not sell, it is expensive for LEGO to unbox and resort the combination into other product combinations). Hence, the best strategy for LEGO is to be reactive. One goal is to have the mold ready for mix-and-match and box them quickly according to the demand for a certain product combination.

This means that LEGO has to have the SKUs ready to place them in the product box and ship out the product quickly, which can be achieved by

(a) Running the manufacturing plant at huge volume scale, and have thousands of units of inventories ready to assemble.

(b) Be located geographically very close to market demand.

Note that Lego’s high margin market is in Europe and North America, but the production costs there are high. This is the trade-off that has propelled LEGO to move into production units into nearby cheaper locations such as Hungary, China, and Mexico – all of which are cheaper for production, and still reasonably close to the customer market demand.

The flip side of managing high volume production is the impact of a negative demand shock. If the demand for lego toys go down, the production facilities would be left with tons of inventory.

Issue 2: Shift to “Promotions” and “quick flight” products.

The second problem is related to a recent trend. Instead of selling steady-selling products, Lego has been increasingly eyeing tie-in promotions with movie studios. (Ninjago movies, Batman movies, and other superhero movies). Such a strategic move shifts the product portfolio from a set of products that sell steadily over time, to a portfolio containing “high-impact” short-run products. (See picture above).

Most of the movie-promotions and tie-ins last only a couple of weeks. Worse, the product sales are correlated with movie quality (not controlled much by Lego), much more than they are correlated with product quality (that is under Lego’s control). There was not much demand for John Carter Legos, even though I am positive that the John Carter Lego set had high production quality.

When combined with issue 1 of capacities, the second issue exacerbates the problem Lego faces. Together, these issues imply that Lego needs large volumes of finished goods inventory on the shelf for those two weeks (with possible high demand if the movie is good, but no demand if the movie is terrible). Then, what happens to all the inventory left at the stores or warehouse?

—

Unfortunately, these problems are not going away.

On one end, the Lego production process is a cheap and scalable injection mold extrusion production process. On the other end, the demand market is becoming unpredictable. Essentially, Lego has moved from steady sellers into the world of studio business, one rife with unpredictability and uncertainty — looking for blockbusters and mega-hit toys.

Remember Hatchimals – the biggest toy hit of 2016? Estimated 2 million toys were sold, totaling revenues of 80M dollars. This year, the sales were not even close.

—

If you like what you read, I welcome you to subscribe to OWL Mail and have the blog digest delivered to your inbox. It’s free and I respect your privacy (no spam).